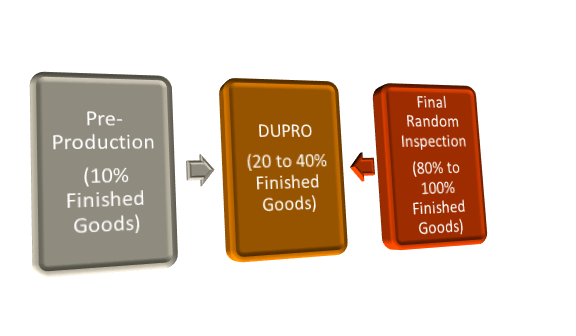

When 20% - 40% of the goods had been checked and packed, or the percentage specified by the applicant. It usually takes place once some finished products have come out of the lines. If quality issues are found, what is already produced might be re-workable, and corrective actions can be taken for the rest of the job.

Inspection at this middle stage allows for checking the goods during various production processes, in addition to checking material use and workflow

By inspecting products during the various processes of manufacturing we can pinpoint problems and effectively control before they move any further down the production line.

Validate your process, before it is too late.